Kitchen Fire Suppression Systems Decoded

Protecting Colorado Kitchens from One of the Leading Causes of Commercial Fires

Commercial kitchens are fast-paced, high-risk environments where heat, oils, and open flames come together — creating significant fire hazards. In fact, cooking-related fires are one of the most common causes of property loss in restaurants and commercial food service facilities.

That’s why kitchen fire suppression systems are required by code in most commercial kitchens. They provide targeted, automatic protection when a fire breaks out — helping protect people, property, and your business.

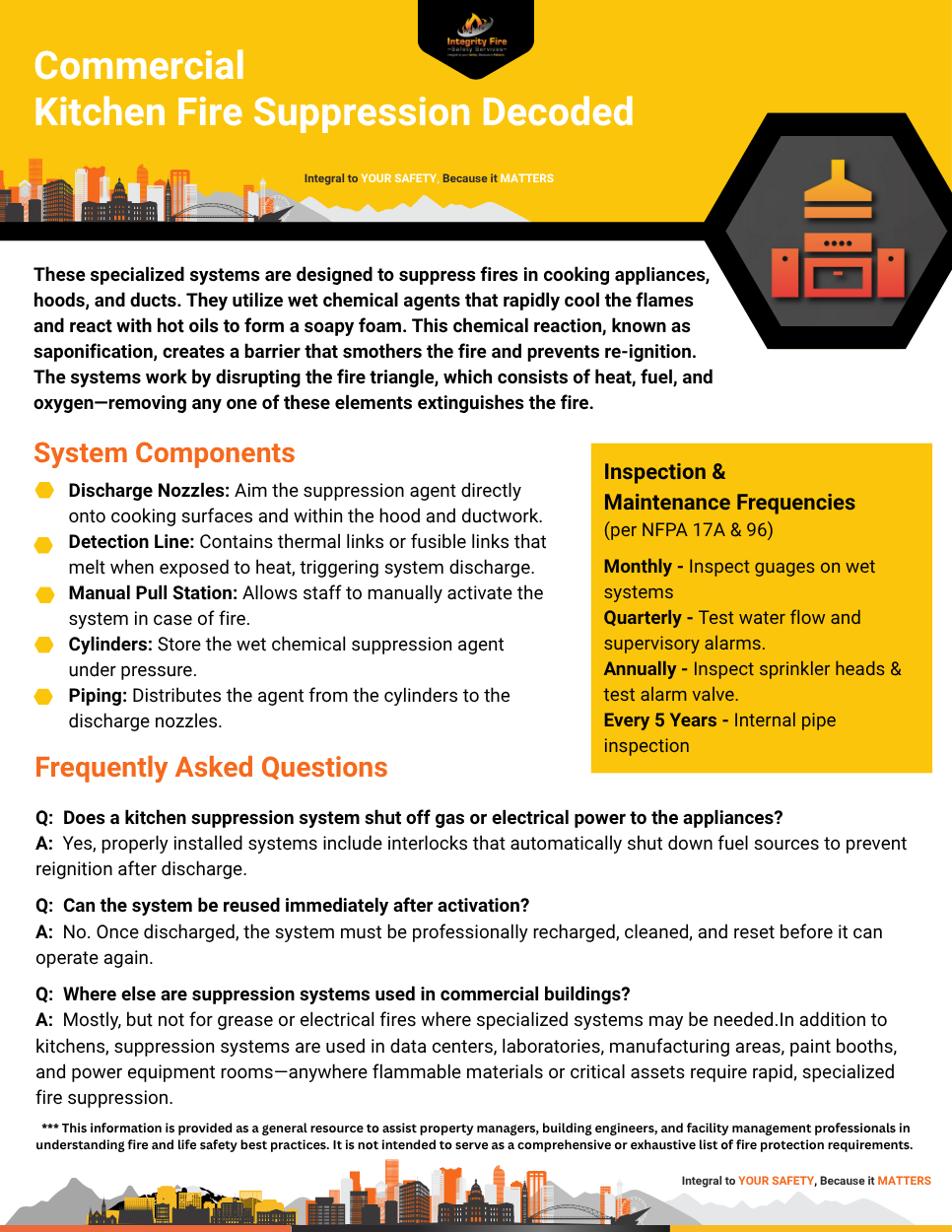

How Kitchen Fire Suppression Systems Work

Kitchen fire suppression systems are specially designed to combat fires involving cooking oils, fats, and high-temperature appliances.

They use a wet chemical suppression agent that rapidly cools the flames and reacts with hot oils to form a soapy foam — a process called saponification. This foam:

- Smothers the fire

- Cools the surface

- Prevents re-ignition

These systems work by disrupting the fire triangle (heat, fuel, oxygen). Removing any one of these elements extinguishes the fire.

Psst! Want to share this Resource with your team?

We've created a convenient print-out of "Kitchen Fire Suppression Systems Decoded" that you can download, print, and share! (Preview below)

Click Here

Core Components

- Discharge Nozzles — Aim suppression agent directly onto cooking surfaces and into hood and ductwork.

- Detection Line — Contains thermal or fusible links that melt when exposed to heat, triggering system discharge.

- Manual Pull Station — Allows staff to manually activate the system in case of fire.

- Cylinders — Store the wet chemical suppression agent under pressure.

- Piping — Distributes the agent from cylinders to discharge nozzles.

Kitchen Fire Suppression System Interaction Sequence

- Heat from a cooking fire activates the thermal detection line or fusible link.

- Suppression system automatically discharges wet chemical agent.

- Agent rapidly cools and forms a soapy blanket over cooking surfaces.

- Integrated interlocks shut down fuel or power sources to the cooking equipment.

- Manual pull station can also activate the system at any time.

Common Questions About Kitchen Fire Suppression Systems

Does a kitchen fire suppression system shut off gas or electrical power to the appliances?

Yes. Properly installed systems include interlocks that automatically shut down fuel or power sources to prevent re-ignition after discharge.

Can the system be reused immediately after activation?

No. Once discharged, the system must be professionally recharged, cleaned, and reset before it can operate again.

Where else are suppression systems used in commercial buildings?

In addition to kitchens, suppression systems are used in:

Data centers

Laboratories

Manufacturing areas

Paint booths

Power equipment rooms — anywhere flammable materials or critical assets require specialized fire suppression.

Kitchen Hood Inspection & Maintenance Cycle

Frequency | Inspection / Maintenance Tasks |

Monthly | Inspect gauges and overall system readiness |

Quarterly | Test alarms and supervisory devices |

Annually | Full system inspection and functional test |

Every 5 Years | Internal pipe inspection |

Regular inspection ensures:

- Reliable system performance

- Code compliance

- Readiness to protect life and property in a fire emergency

Why it Matters:

Because in a commercial kitchen fire, seconds count and readiness matters.

At Integrity Fire, we understand that protecting kitchens requires specialized expertise. These are not “set it and forget it” systems — they require ongoing maintenance and proactive attention.

We help clients across Colorado:

- Conduct thorough NFPA-compliant inspections and testing

- Provide clear documentation for AHJ reviews

- Recharge and reset systems after activation

- Train kitchen staff on proper use and manual activation

- Integrate kitchen suppression into the building’s overall fire & life safety plan.

Bottom Line: Is Your Kitchen's Fire Suppression System Ready?

If it’s been more than a year since your last system inspection — or if your kitchen staff isn’t fully trained on activation procedures — now is the time to take action.

We’ll help ensure your system is ready to protect your people, your property, and your business.- Because it matters.

CONTACT US

Schedule your next inspection with Integrity Fire Safety Services today!